Your cart is currently empty!

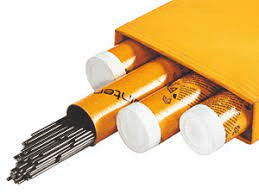

UTP DUR 600

UTP DUR 600 is universally applicable for cladding on parts of steel, cast steel and high Mn-steel, subject simultaneously to abrasion, impact and compression. Typical application fields are the earth moving and stone treatment industry, e.g. excavator teeth, bucket knives, crusher jaws and cones, mill hammers etc., but also for cutting edges on cold cutting…

Description

UTP DUR 600 is universally applicable for cladding on parts of steel, cast steel and high Mn-steel, subject simultaneously to abrasion, impact and compression. Typical application fields are the earth moving and stone treatment industry, e.g. excavator teeth, bucket knives, crusher jaws and cones, mill hammers etc., but also for cutting edges on cold cutting tools. Hardness of the pure weld deposit 56 – 58 HRC After soft–annealing 780 – 820° C / oven approx. 25 HRC After hardening 1000 – 1050° C / oil approx. 60 HRC 1 layer on high Mn-steel approx. 22 HRC 2 layers on high Mn-steel approx. 40 HRC UTP DUR 600 has excellent welding properties due to a quiet arc, an even flow and a good weld build-up, easy slag removal. Machining of the weld metal possible by grinding.

Reviews

There are no reviews yet.