Fixed Gas Sampling

Fixed Gas Sampling

Fixed Gas Sampling

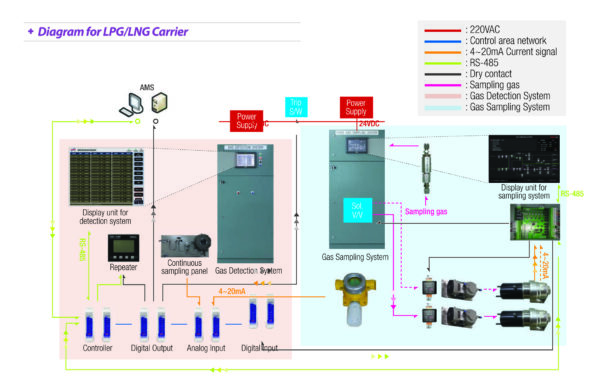

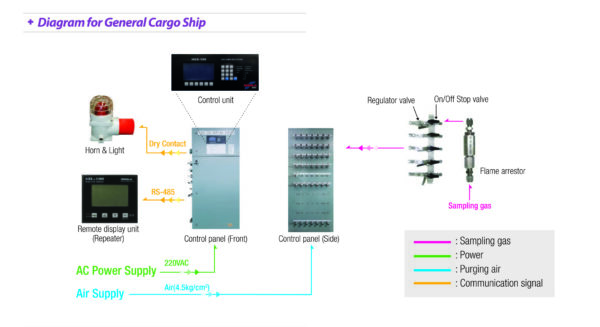

The Fixed gas sampling system is dedicated to the Gas Control in all Tanks, Void Spaces, Pump room or Houses adjacent to Cargo Storage Tanks and Handling Systems. In order to detect any Gas Concentration level over programmable limits and to monitor visible and audible alarms consequently, these areas are controlled by the suction process sampling on one or more common sensor(s) as well as by individual local sensors.

This system complies with ISGOTT regulation chap. 7.8 and 8.2.

Select Quantity:

Features

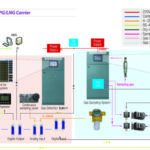

The Fixed Gas Sampling System is composed of :

- Analysing Unit

A cabinet named Analyzing Unit includes suction process sampling gas sensor(s) and pneumatic components for up to 48 channels (pumps, solenoid valves, water trap filter & pressure sensor). A modular arrangement of solenoid valves allows easy sizing of channels number, easy extension as well as easy maintenance. An electronic module manages above parts, monitors up to 7 gas sensors dispatched either in suction process or as local sensor, performs all gas measurements from above sensors, and monitors the alarms on dry contact outputs. It comprises of 4 digital RS485 communication ports Unit(s) as described hereunder, and/or an external Monitoring System using MODBUS RTU protocol. The Unit is powered equally by 220 or 110 VAC. - Control Unit

One or more panel(s) named Control Unit include an electronic module managing a LCD screen for measurement and alarms display, status lamps, buzzer/dry contact output for alarms monitoring and keyboard for System operation and configuration. The large LCD screen increases the data availability and the man-machine interface is simplified for easy access to functions and configuration using spread menus. One Control Unit can be incorporated in the Analyzing Unit or located in a remote box, another one can be located in another place. The Control Unit is powered by 24VDC from the Analyzing Unit, and communicates with it by RS485 link.